Project from 3D constructor - https://dubina.biz

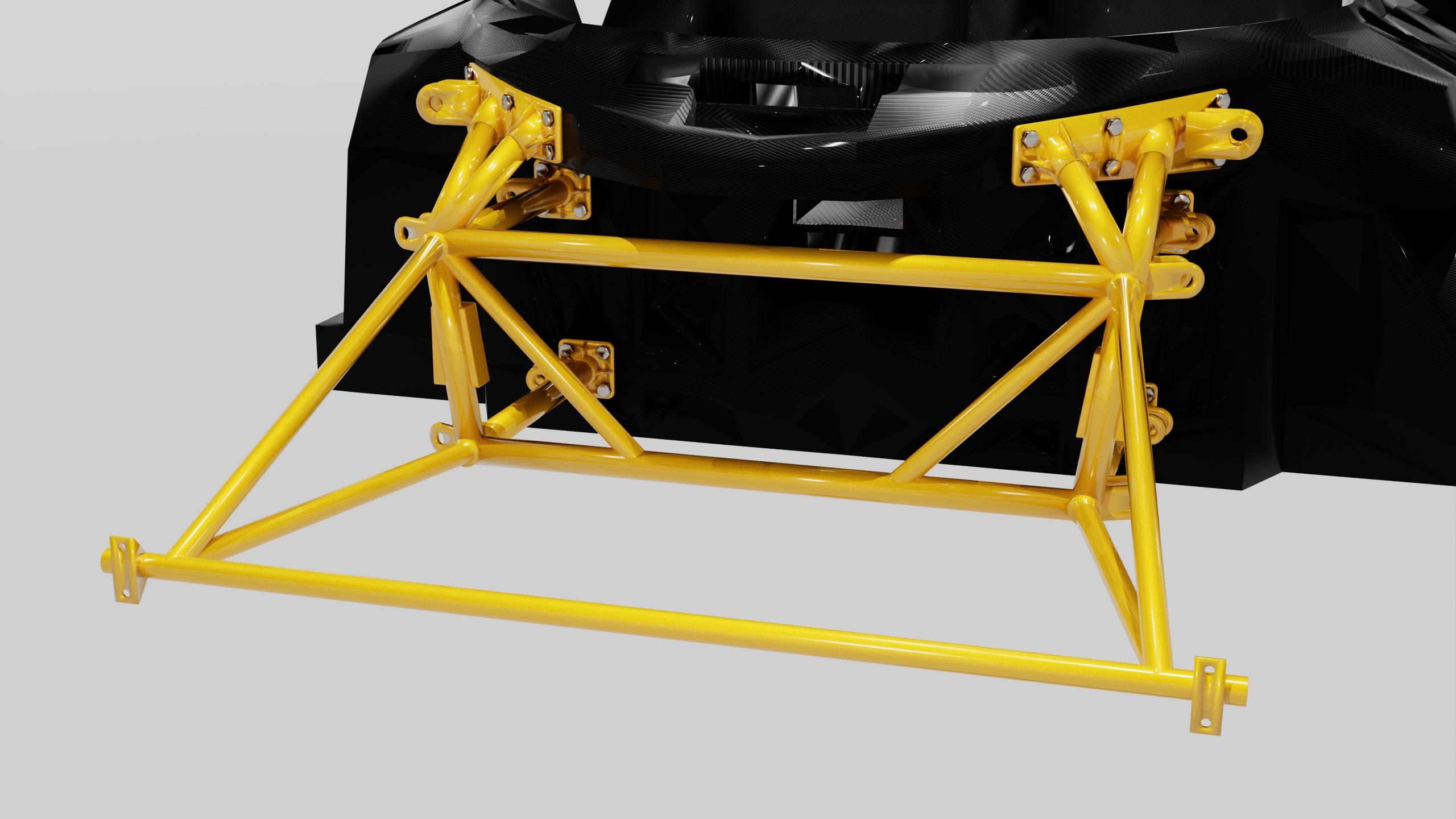

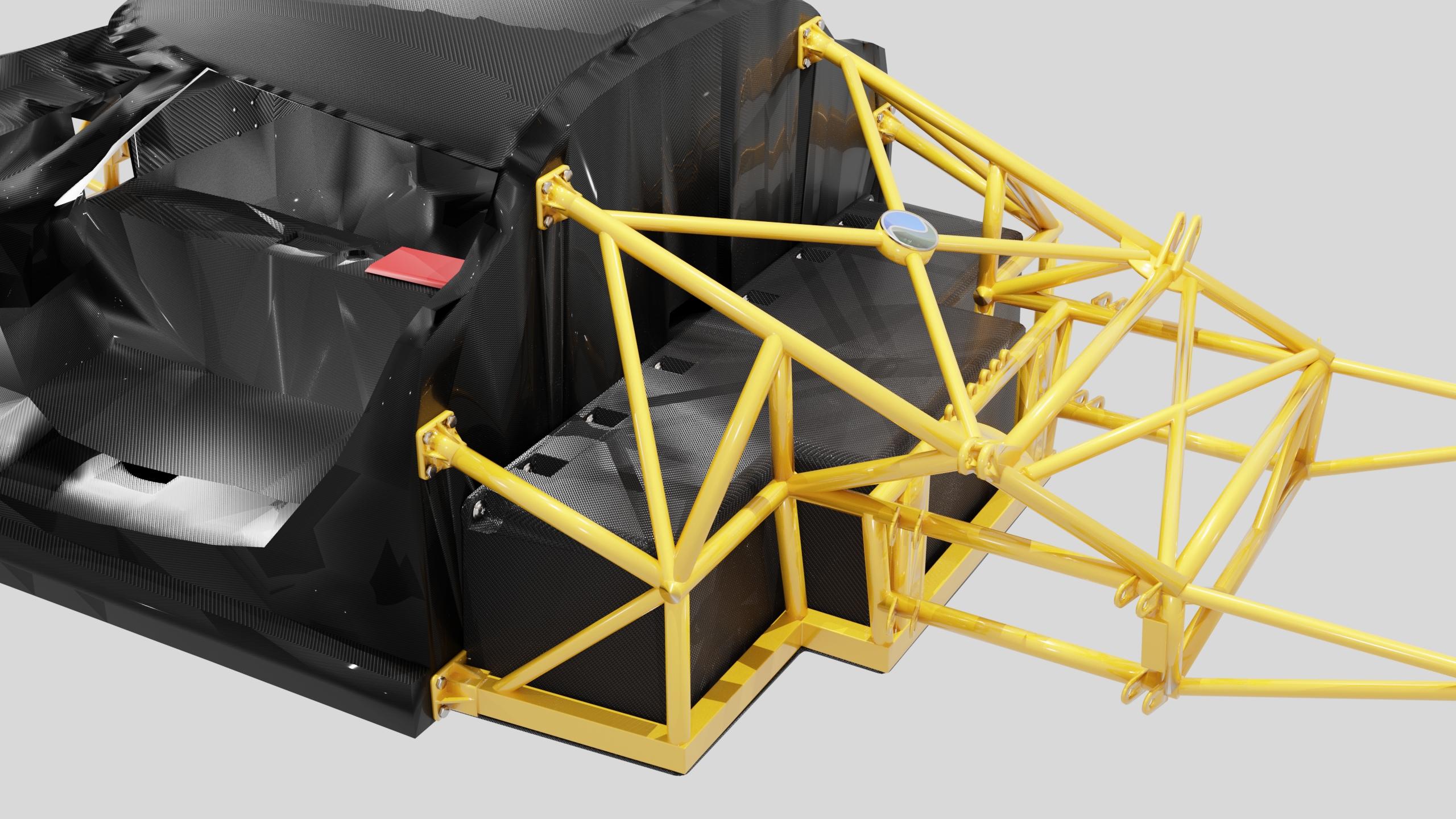

The car frame consists of two parts: front and rear. They are attached to the monocoque at the front and rear. The front frame holds the front suspension, anti-roll bar, front trunk, front bumper, and headlights. The rear frame holds the rear motors, battery, rear suspension, anti-roll bar, rear trunk, rear bumper, and taillights. The frame design is based on complete triangulation of all planes. Triangulation is the process of dividing a polygonal area with a complex configuration into a set of triangles. The advantage of this type of design is its combination of lightness and high rigidity and strength. When designing the frame, load-transmitting areas were taken into account. These areas contain nodes that distribute the load evenly across all parts of the frame. To increase the rigidity of the rear frame, a crossbar is installed between the shock absorber mounts. The frame is made of structural aluminum alloy 6061. Aluminum has a number of advantages over other metals: low weight, high strength, good weldability, corrosion resistance, resistance to temperature changes. Alloy 6061 has a good combination of mechanical properties. It is able to withstand significant loads before failure. The tensile strength is 310 MPa. Its modulus of elasticity is 68.9 GPa. Alloy 6061 is heat treated to increase strength. It becomes stronger after tempering. This alloy is easily joined by welding, easily processed by milling, drilling, and easily deformed into the desired shapes. Alloy 6061 has a low density of 2.7 g / cm3. It has good corrosion resistance. The high corrosion resistance of the aluminum alloy is due to the formation of an oxide film of Al2O3. It is non-reactive with elements that cause metal corrosion. Magnesium (Mg) and silicon (Si) are used as the main alloying elements. They give the alloy strength and resistance to corrosion. Due to the copper content, alloy 6061 is slightly less resistant to corrosion than other types of alloys (5052, does not contain copper). Alloy 6061 has good resistance to corrosion from concentrated nitric acid, as well as ammonia and ammonium hydroxide. The chemical composition of alloy 6061: 97.9% Al, 0.6% Si, 1% Mg, 0.2% Cr, 0.28% Cu. Using a standard profile for the frame makes the assembly process easier. The frame design consists of simple elements: round tubes, square tubes, angles, plates. This type of design has a low cost. It is easier to operate and repair. Installation and dismantling of parts inside the frame is easier due to the large distance between the tubes. The round shape of the tubes distributes the load well. The sections of the frame in places of high load are made of pipes with a diameter of 40 mm and a wall thickness of 5 mm (Ø40x5 mm). The sections in places with a lower load are made of pipes with a smaller diameter of 30 mm and a wall thickness of 3 mm (Ø30x3 mm). The place of attachment of the battery and motors are made of a square tube 55 mm and a wall thickness of 5 mm. (55x5 mm). The places of attachment of the suspension arms are made of 8 mm thick plates. To increase the strength and rigidity of the frame, 6 mm thick gussets are welded to the joints of the pipes. The open ends of the pipes are welded to prevent water and dirt from getting inside the pipes. This is done using square blanks of 1.5 mm thick sheet aluminum. Before welding, the pipes are cut to the dimensions of the drawing and marked. After cutting, the pipe sections are placed on a welding table-staple. Coordinating the position of the pipes with the dimensions in the drawing, the pipes are fixed with special devices. Magnetic squares are used to set the required angle. Then the pipe sections are fastened with several welding spots. After checking all the dimensions and angles, the final welding of all the seams takes place. All the seams are bypassed sequentially, from one side to the other, to avoid gaps. The strength and integrity of the frame will be sufficient only with strict compliance with the drawings and high-quality welding. When preparing the frame parts for welding, special attention is paid to the fitting of the elements. Uniform adhesion of the parts to each other along the entire perimeter of the joint and minimal gaps are ensured. This eliminates the occurrence of unnecessary stress in the structure, ensures high quality of seams and the proper strength of the frame. Pipes made of aluminum alloy 6061, square and round cross-section, are welded together using the method of semi-automatic pulsed electric arc welding with a consumable electrode in an argon inert gas environment (MIG), forming strong permanent joints in the frame.

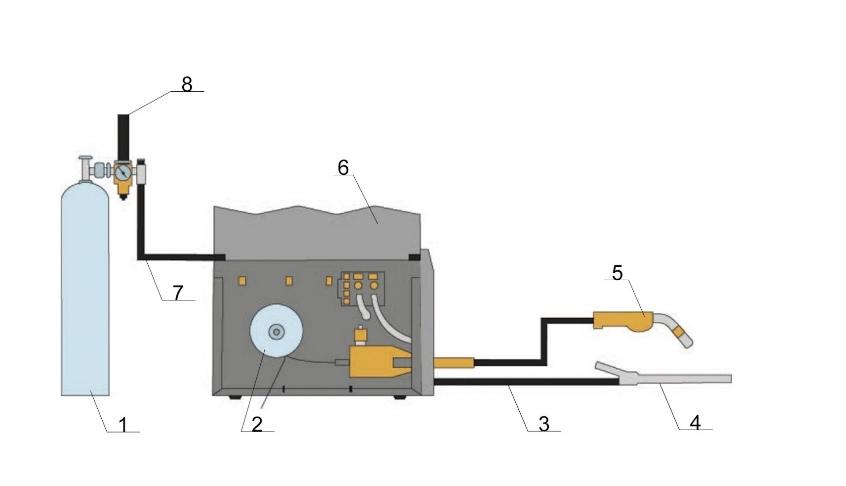

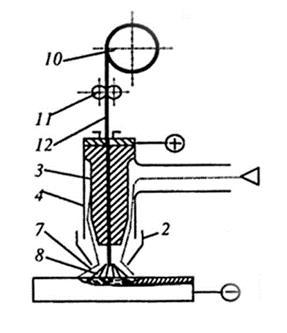

Semi-automatic pulsed electric arc welding with a consumable electrode in an inert argon gas environment.

Aluminum and its alloys have specific properties compared to steels, which make their welding process comparatively difficult. These properties include the following: tendency to pore formation; high thermal conductivity, high affinity for oxygen and formation of stable oxide Al2O3 in the form of a film covering the surface of parts; significant excess of the melting point of the oxide film (2050 °C) over the melting point of aluminum (660 °C); high coefficient of linear expansion; tendency to form hot and cold cracks; excess of the density of the oxide film over the density of the metal itself, reduction of the strength properties of the welded joint compared to the base metal; fluidity; sudden transition from solid to liquid state when heated; high absorption of hydrogen during welding. Aluminum is quite capricious in terms of welding, since it has an oxide film. The melting point of the oxide is 2050 °C. Therefore, in order to break it down with an electric arc, a high current is required. But the aluminum itself melts under the oxide after 600 °C. It turns out that with a high welding current: the liquid bath is scattered to the sides; it is difficult to control the arc; the number of undercuts and burns increases. If the current is reduced, it will not be possible to burn through the oxide film - all the filler metal will remain on the surface, and not fuse with the base metal. This will make the joint weak, not hermetic. Therefore, a MIG device is used that can automatically change the current during welding. Burn through the oxide at high current, and weld the base metal at low current. This mode is called pulsed. For welding aluminum alloy 6061 using the MIG method, a universal MM215 device is used. This welding machine operates with a welding current of 20 to 230 A, a voltage of 240 V and weighs about 29 kg. It is equipped with technology that simplifies setting up welding parameters. It also has a function for soft starting of welding. The welding process is carried out with a torch controlled manually by the welder. The ER4043 aluminum filler wire is fed automatically. Since aluminum is a fluid metal in molten form, the connection is made in the lower position. The most important process that occurs during arc burning in MIG is the transfer of the melting metal of the electrode wire to the weld pool. The nature of this process is influenced by such factors as the composition of the protective gas environment, current, arc voltage, material and diameter of the electrode wire. Depending on these conditions, the melting material passes into the weld pool in a short pulse. Through the filler wire-electrode, the optimal amount of alloying elements and deoxidizers enters the weld pool, which ensures an excellent connection. The alternating current mode allows you to automatically switch the polarity of the current during the welding cycle. As a result, at the beginning of the cycle, the oxide film is destroyed, and during the next cycle, deep and dense fusion of aluminum is achieved. Setting the polarity and balance of the current allows you to adjust the cleaning zone and the depth of penetration. The quality of the future weld depends on the preparation of the surface of the workpiece. Before work, each product is cleaned, even if no traces of oil, chips or other contaminants are visible on its surface. The oxide film is removed mechanically and chemically. The surface is cleaned mechanically, then the working surface of aluminum is treated with a solvent (acetone, gasoline, white spirit), after which the product is dried before the welding cycle. For the mechanical cleaning method, sandpaper and wire brushes are used. For the chemical method, alkaline solvents are used, followed by rinsing in hot and cold water and drying the workpiece. All welds are of the highest possible quality with full penetration. The weld completely encircles the perimeter of the pipe. After welding, welding beads are removed, sharp corners and edges are rounded off, all surfaces are ground. Usually, after welding, the properties near the weld are about 40% of the strength of the entire metal. Therefore, to give strength, the frame is subjected to heat treatment - tempering. After heat treatment, the frame is covered with a protective primer.